-

Płyta warstwowa Rockwool

-

Płyta warstwowa z wełny szklanej

-

Płyta warstwowa z poliuretanu

-

Akustyczny panel warstwowy

-

Metalowe panele okładzinowe

-

blacha perforowana

-

Profilowana blacha stalowa

-

Stalowe poszycie podłogowe

-

Aluminiowy panel warstwowy

-

Magazyn stali prefabrykowanej

-

Składany dom kontenerowy

-

Płyta warstwowa EPS

-

Dekoracyjny panel warstwowy

-

Narożnik panelu warstwowego

-

Węzeł ze stali

-

Izolacja z wełny szklanej

-

Izolacja z wełny skalnej

-

Belka stalowa konstrukcyjna

-

Stalowy kąt

-

Sekcja kanału stalowego

-

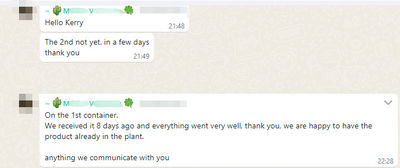

PAN„Otrzymaliśmy go 8 dni temu i wszystko poszło bardzo dobrze, dziękujemy, cieszymy się, że go mamyprodukt już w zakładzie. Wszystko, co komunikujemy z Tobą"

PAN„Otrzymaliśmy go 8 dni temu i wszystko poszło bardzo dobrze, dziękujemy, cieszymy się, że go mamyprodukt już w zakładzie. Wszystko, co komunikujemy z Tobą" -

PAN„Cześć Kerry, przeprowadziliśmy dalsze testy na panelu i jesteśmy zadowoleni z wyników”.

PAN„Cześć Kerry, przeprowadziliśmy dalsze testy na panelu i jesteśmy zadowoleni z wyników”.

Steel Structure Large-scale Auto Parts Factory Industrial Prefab Workshop Customized Warehouse Automobile Serviced Warehouse

| Place of Origin | Hebei,China |

|---|---|

| Nazwa handlowa | BAODU |

| Orzecznictwo | ISO9001,CE |

| Model Number | Steel Warehouse |

| Dokument | Broszura produktu w wersji PDF |

| Minimum Order Quantity | 1000square meters |

| Cena | CN¥200-430/square meter |

| Packaging Details | In general, for steel structure , we use the steel frame packing to keep goods not to be broken . For sandwich panel and color steel sheet, we use the plastic packing . If the clients need special packing will according to their requirements. |

| Delivery Time | 30days |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability | 10000 Square Meter/Square Meters per Month |

Skontaktuj się ze mną, aby otrzymać bezpłatne próbki i kupony.

WhatsApp:0086 18588475571

czat: 0086 18588475571

Skype'a: sales10@aixton.com

W razie jakichkolwiek wątpliwości zapewniamy całodobową pomoc online.

x| Product Name | Steel Structure Large-scale Auto Parts Factory Industrial Prefab Workshop Customized Warehouse Automobile Serviced Warehouse | Warranty | More than 50 years |

|---|---|---|---|

| Main frame | Welded H Steel Beam, Steel Truss | Installation | Engineer guidance |

| Surface treatment | Painting or galvanized | Processing Service | Bending, Welding, Decoiling, Cutting, Punching |

| Application Fields | Warehouse, factory, steel structure building | Frame | Weld steel structure frame |

| Secondary Frame | C&Z Purlin, Brace | Installation Guide | installation drawings and video |

| Foundation | Bolt-Connected Precast Concrete Base | Design | SAP2000/AutoCAD /PKPM /3D3S/TEKLA |

Steel Structure Large-scale Auto Parts Factory Industrial Prefab Workshop Customized Warehouse Automobile Serviced Warehouse

![]()

Features:

1,Steel structure has light weight;

2,Steel structure has good seismic and impact resistance;

3,Steel structure manufacturing is highly industrialized;

4,Steel structures can be assembled accurately and quickly;

5,The building can be recycled after disassemble;

6,Steel structure building construction peroid is short.

Technical Parameters:

![]()

![]()

If you have drawings, welcome to share drawings with us, quoation will be done based your drawings. Our excellent design team will

design the steel structure workshop warehouse for you. If you give the following information, we will give you an satisfactory drawing.

1 Location (where will be built? ) which country? which city?

2 Size: Length*width* Eave height _____mm*_____mm*_____mm

3wind load (max. Wind speed) _____kn/m2, _____km/h, _____m/s

4 snow load (max. Snow height) _____kn/m2, _____mm, temperature range?

5 anti-earthquake _____level

6 brickwall needed or not If yes, 1.2m high or 1.5m high? or other?

7 thermal insulation If yes, EPS,fiberglass wool, rockwool, PU sandwich panels will be suggested; If not, the metal steel sheets will be ok. The cost of the latter will be much lower than that of the former.

8 door quantity & size _____units, _____(width)mm*_____(height)mm

9 window quanity & size _____units, _____(width)mm*_____(height)mm

10 crane needed or not If yes, _____units, max. Lifting weight____tons; Max. Lifting height _____m

If you are interested in our products,you can contact us at any time.

Steel Materials List:

![]()

|

|

Steel Building Process:

![]()

![]()

Project Cases:

![]()

![]()

![]()

![]()

![]()

![]()

Strict Quality Inspection Standards

![]()

![]()

Excellent product quality is our eternal pursuit, and it is also the fundamental reason for us to base ourselves on the global market. BAODU GROUP implements whole-process quality management and strictly supervises every process such as raw material supply, engineering design, steel component manufacturing, installation and construction.

We have established a professional team of quality inspection engineers, introduced internationally leading quality inspection equipment such as German GS1000 vacuum spectrometer and high-frequency infrared carbon sulfur analyzer, established a high-quality product inspection room, and won many awards from China's advanced quality management unit.

In addition, we support testing and certification by SGS, TUV, BV.

Our capacity and certification:

![]()

![]()

![]()

![]()

![]()

Support and Services:

![]()

![]()

![]()

![]()

![]()

![]()

Company profile:

Baodu International Advanced Construction Material Co., Ltd was established in January 2010 with the office in Beijing and factory in Hebei, China. Baodu is a designer, manufacturer, supplier and exporter of industrial noise comprehensive treatment, steel structure, sandwich panel and prefab house. Baodu has an annual output of 6 million square meters of acoustic sandwich panels, 100000 tons of steel structures and 1 million square meters of floor decking sheet. The products are sold in more than 30 countries and regions around the world. Baodu has a professional design team with more than 10 years’ experience, including 5 senior engineers, 20 engineers, and 35 technicians. Baodu has several energy saving and environment protection intellectual property rights, construction and environment protection design qualification, CE certification and Russian GOST certification etc. Baodu participated in the military parade village project for the 60th anniversary of China and project of Beijing Daxing International Airport. Under the guidance of China's "one belt, one road" strategy, Baodu has also undertaken overseas projects such as the project of Thar,Pakistan coal fired power plant, Hasyan Dubai power plant and so on. Finally, welcome your coming to Baodu for a visit and cooperation!

Packing and Shipping:

![]()

![]()

![]()

![]()

Packaging Details :

1.Steel structure components will be in packaging with proper protection.

2.Sandwich panels will be covered with plastic film.

3.Bolts and other accessories will be loaded into wooden Boxes

All the structure components, panels, bolts and sorts of accessories will be well packed with standard package suitable for ocean

transport and loaded into 40’HQ.

All the products are loaded at the loading site of our factory using crane and forklift by our skilled workers, who will prevent

the goods to be damaged.

Good relationship with many vessel companies to make sure the transportation smooth

FAQ

1. Do you provide on-site installation service?

we can provide Installation guide service based on customers' request.

2.What's your delivery time?

Salesman will confirm the time accordingly, large order should communicate with order management department in advance. Normally, delivery time is 30days after receiving deposit. Large order delivery time should be arranged separately.

3.How to control the quality of your product?

a. quality of the design: think about possible problems in advance and provide a high-quality design solution. b. quality of the raw material: choose the qualified raw material c. quality of the production: precise manufacturing technique, experienced workers, strict quality inspection.

4. What designs do you have in different climates (How can the products adopt to different climates)?

Strong wind region: improve the wind-resisting ability of the internal structure. Cold region: increase the thickness of the wall, or use good insulation material, improve the anti-pressure ability of the structure. High corrosion region: use corrosion resistant material, or paint anticorrosive coating.